Project Management Systems

At Aionmach, we have streamlined our custom manufacturing process into an efficient and well-coordinated system designed for precision and reliability.

Quoting:

Customers share their designs requesting pricing and delivery estimates. Our quoting team meticulously evaluates the required manufacturing processes, identifies necessary materials, calculates costs, and incorporates additional expenses such as subcontract services for processes like painting, plating, or heat treating. Using our Enterprise Resource Planning (ERP) software, this data is compiled to create a detailed method and comprehensive quote tailored for the client.

Purchase Order Review:

Once a customer submits a purchase order, it is carefully logged into our ERP system. During this stage, we thoroughly examine all quality clauses, ensuring compliance before setting up a job based on the method developed during the quoting phase.

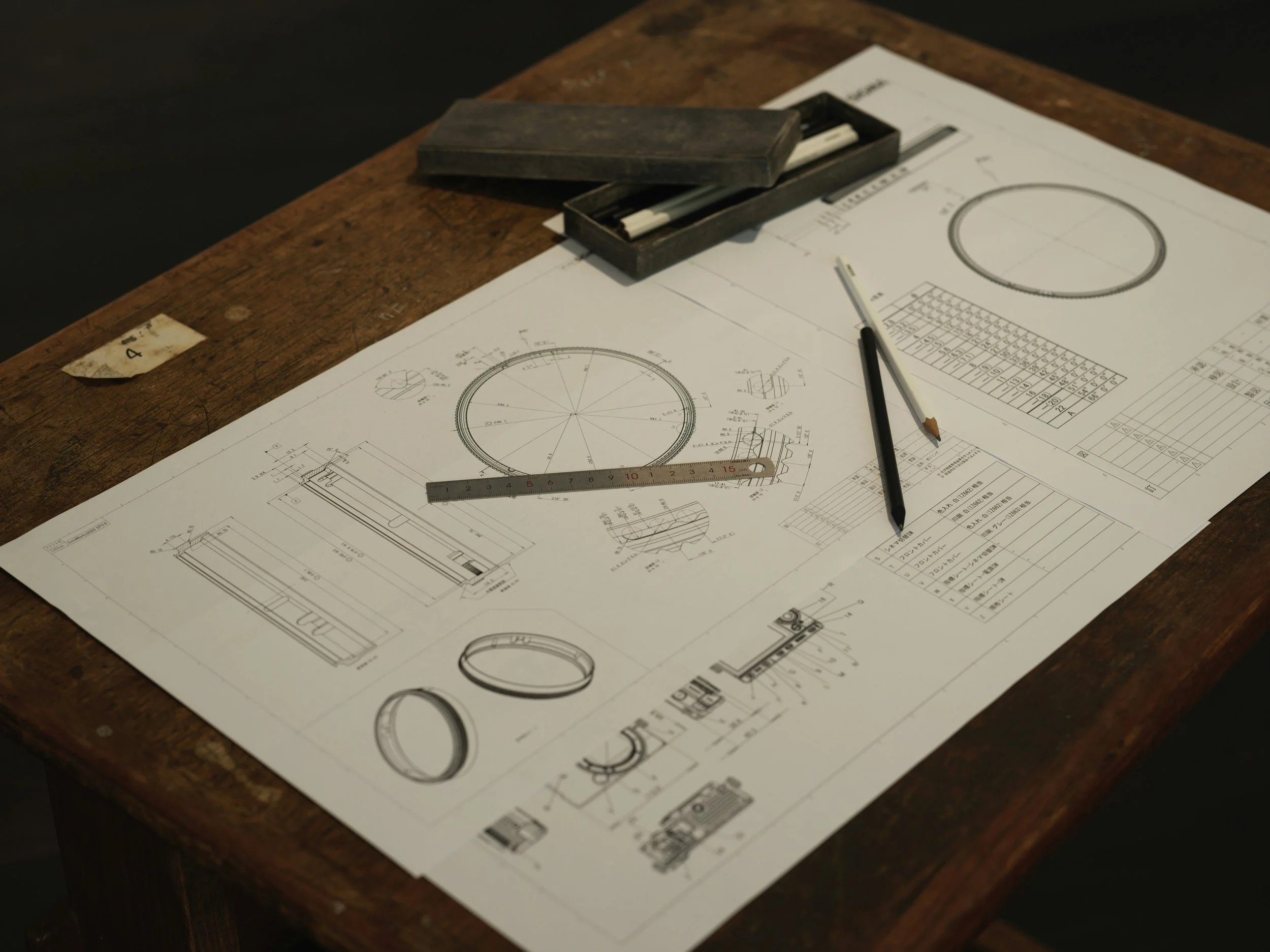

Engineering Review:

Before production begins, our engineering team performs an in-depth review to optimize efficiency and ensure accuracy. This involves verifying drawing tolerances, generating inspection reports, and refining materials or methods as necessary to meet any customer specifications that may not have been addressed during quoting.

Purchasing:

The purchasing team receives detailed material specifications from engineering, covering aspects such as type, size, and quantity. Given potential time gaps since the initial quoting phase, updated supplier quotes are frequently obtained. All procured materials undergo meticulous inspections upon arrival to confirm their adherence to the necessary physical dimensions and drawing standards.

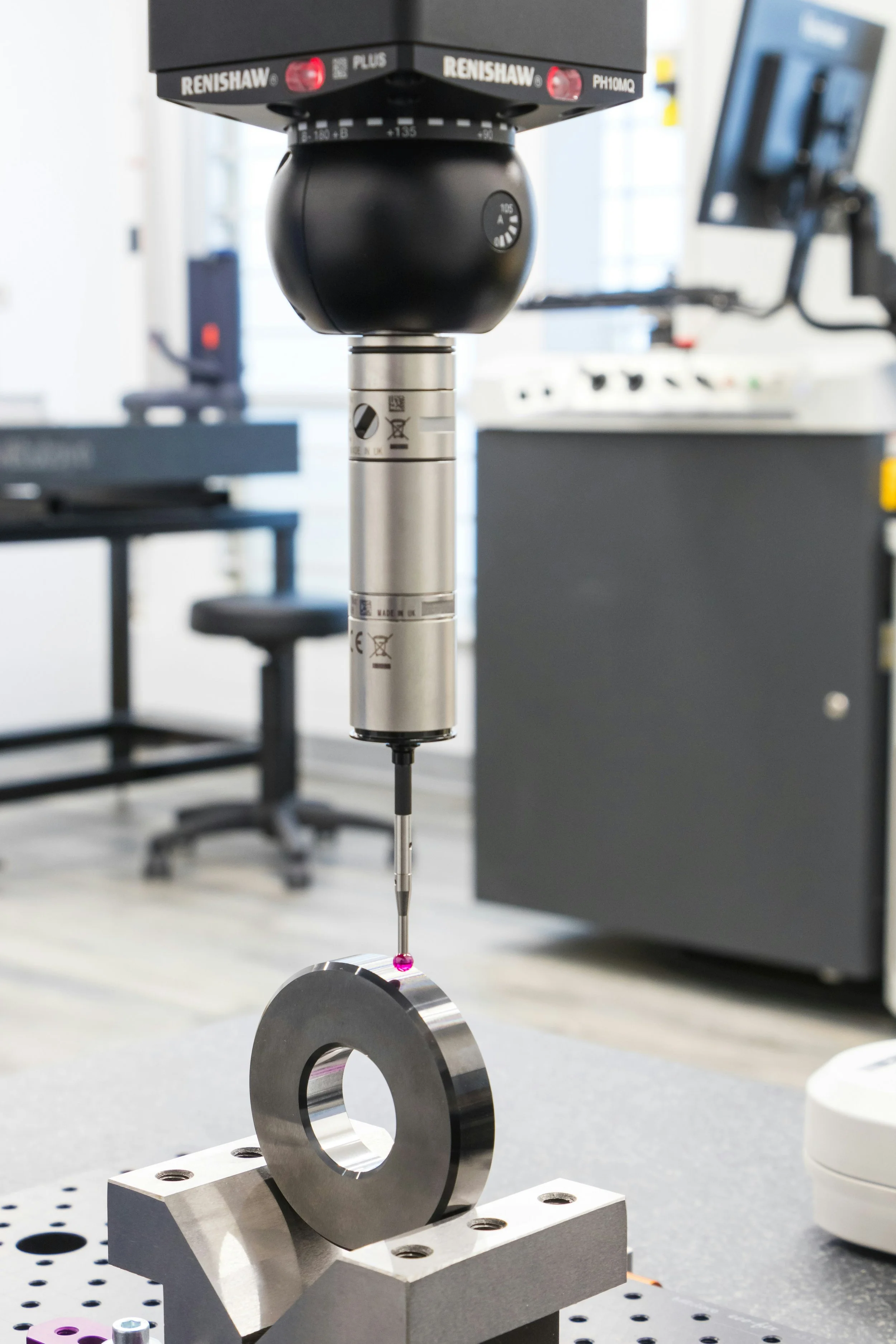

Quality Control:

Quality assurance is integral at every stage of our workflow and follows a multi-step process. Initially, a "first-off" part is thoroughly inspected to confirm compliance with the specified drawings and tolerances. Interval inspections are then carried out after every 10 parts to ensure consistent quality throughout production. Finally, an exhaustive final inspection verifies that every product meets customer requirements and specifications before leaving the facility. Through this refined system at Aionmach, we ensure a seamless manufacturing experience built on accuracy, efficiency, and reliability.

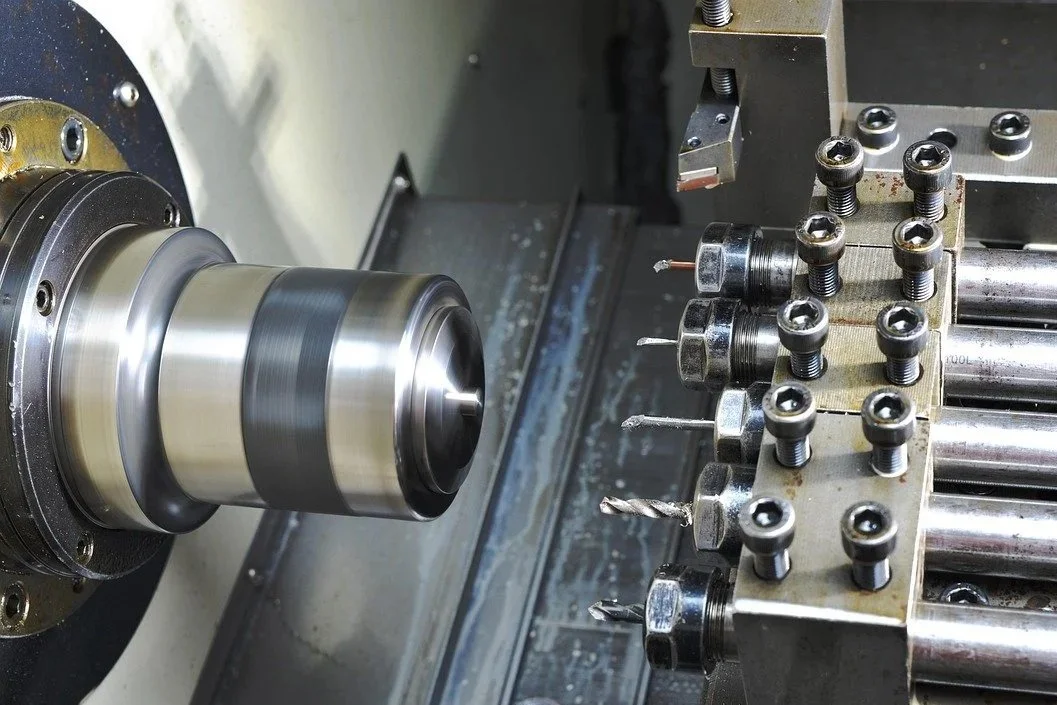

Manufacturing:

This core stage brings projects to life, executed by our skilled team following the outlined job details. Since every project is unique, diverse manufacturing techniques may be employed. The process typically begins with raw materials issued for machining, where they are set up, programmed, and processed by our expert operators. Depending on the project’s requirements, components may undergo subcontracted operations like painting or plating. Additionally, we provide laser marking, etching, and labeling services for precise identification before components proceed to quality checks.